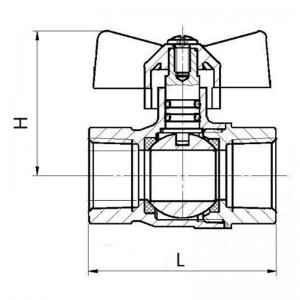

Art. TS 2202 Brass Gas Isolation Ball Valve

Product Details

Art. TS 2202 Brass Gas Isolation Ball Valve

Forged brass body with Aluminum butterfly handle

Female/Female threads

Machined chrome plated brass ball

Nickel plated surface treatment

Nominal pressure: 145 psi (10 bar)

Minimum and maximum working temperatures: -20℃≤t≤60℃

Suitable for: water, Oil, Gas

EN331:2015 approved for use in gas installations in buildings.

Parameter Table

| Size | Dn | Length | Height | Qty/Ctn |

| 1/2" | 15 | 53.5 | 41 | 120 |

| 3/4" | 20 | 61 | 44 | 100 |

| 1" | 25 | 78 | 57 | 48 |

Art. TS 2202 designed for use in GAS pipeline supply systems, and the technical meets EN 331: 2015 standard and get certificate approved, the max inlet Pressure be 10 bar (145 psi) and Operation Temperature at -20ºC to 60ºC, and the Flow capability 5,6 m³/h. Our Gas ball valves take mostly two-piece construction and feature a ¼ turn gas flow on and off, the quality is so these forged brass gas ball valve product 100% already be factory leak tested before delivery.

Valve Material

| No. | Name | Material |

| 1 | Bonnet | Brass |

| 2 | Seat | PTFE |

| 3 | Ball | Brass |

| 4 | Stem | Brass |

| 5 | Double sealing O-ring | NBR/Viton |

| 6 | Body | Brass |

| 7 | Handle | Aluminum |

| 8 | Screw | 304 |

● High-quality materials for Body and Ball: CW617N/CW614N

● Handle: Aluminum or Steel handle with yellow plastic sleeve.

● Standard thread connection: NPT or BSP.

● Certificate Approved: EN 331:2015 approved

How to install the gas ball valve?

In order to avoid that the sealing material and leak, please operate as below:

1. be sure that the two pipes are correctly aligned;

2. during the assembling process the installer has to apply its assembling tools at the end that is nearest to the pipe;

3. the application of the sealing materials of the fitter must be limited at the threat zone. An excess should interfere in the ball-gaskets closure zone, compromising the tightness.

4. while the gas flows into the ball valve, be sure to remove some impurities from the filter valve which install ahead of it, otherwise, they could damage the seals.

5. during the disassembly apply the screw tool should at the end of the valve nearest the pipe.

The main building gas shutoff valve is normally located at the main gas meter and it's very important to shut off the gas flow directly to ensure safety in some cases such as where a damaged or corroded flexible gas connector line joins the appliance to the building gas piping, moving the appliance could start a dangerous gas leak.

As a professional valves manufacturer, we also serious and will provide high-quality products and timely service as a good cooperation start. Tosval offers its customers a range of important services as a partner able to support its competitiveness in increasingly demanding international markets, also besides the constant updating of production facilities, a key factor in maintaining TOSVAL’s current leadership role proved to be the strong attention given to the technical design aspects.

Tosval is certified approved by ISO9001, ISO45001, OHSAS 18001, EN331: 2015, EN 13828:2003, etc.

Art. TS 2202 gas ball valve is compact in structure, reliable in sealing, simple in structure, and convenient in maintenance. The sealing surface and spherical surface are often closed, so it is not easy to be eroded by the medium surface treatment, it is easy to operate and maintain.